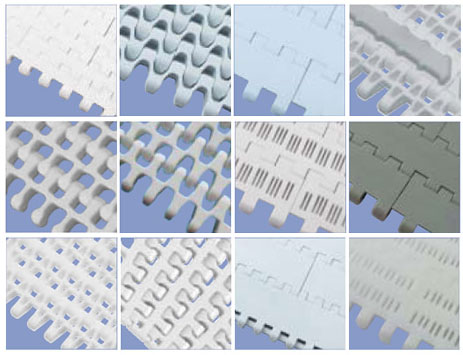

Plastic modular belts are sprocket-driven for positive drive and tracking which virtually eliminates problems associated with mistracking that can lead to belt damage. Flights are assembled as an integral part of the belt, and can be replaced with a minimum of downtime without complicated tools or equipment. The all-plastic design provides maximum corrosion and abrasion resistance, while eliminating concerns of metal contamination.

Belt surface styles can range in open area from 18% to 40% to maximize drainage without compromising belt strength. Belt materials are available in unique colors to provide visual contrast between the belt and the product. All materials are FDA approved and are designed for a wide range of operating temperatures from -90°F to 220°F.

Modular belting is perfect for a wide range of food industry applications such as:

Meat and Poultry Industry

- Saw Lines

- Boning and Pace Tables

- Fat and Trim Lines

- Bone Conveyors

- Incline Conveyors

- Box Handling

- Grading and Inspection

- Weigh Scales

- Metal and Bone Detection

Fruit and Vegetable Industry

- Primary & Secondary Wash

- Inclines & Elevators

- Grading & Sorting

- Coolers, Sterilizers & Exhaust Boxes

- Container Handling

- Metal Detectors

Confectionery Industry

- Chocolate Bars

- Molded Chocolates

- Chewing Gum Processing

- Candy Processing (Hard and Soft)

Bakery Industry

- Hearth Bread processing

- Bread and Bun processing

- Flatbread processing

- Puff Pastry Dough

- Biscuit Manufacturing

- Baked, Salty and Direct Expanded Snacks

Beverage Industry

- Dairies

- Breweries

Great Lakes Belting also offers a full line of Radius and Straight Chains and Sprockets. Please call 1-800-545-2358 today for more information.