We understand that no two applications are alike and, because of that, that no two solutions are alike. We focus on developing specific products to address specific issues. Whether we’re creating a new belt design or developing a new system from the ground up, we can work with you to redesign our products so that you don’t have to redesign your process.

Best of all, our production capabilities are so cost-effective, we can provide affordable custom materials and products on even the smallest scale, down to a single roll of belting. At Great Lakes Belting, small customers — and small orders — get the same kind of specialized service and attention that’s usually reserved for only the biggest customers.

Cleats

To ensure efficiency and compatibility, Great Lakes Belting offers a wide range of cleats. Designed to convey materials along your belt’s route, we can provide you with rib cleats, T-cleats, box cleats, super cleats, angled scoop cleats, and more. With the ability to customize cleats to your line’s specific needs, our team will work with you to design and deliver the products you need.

V-Guides

Ensuring that your belt has proper support, V-guides are engineered to help you avoid mistracks and maintain productivity. At Great Lakes Belting, we offer a number of V-guides, including cast urethane, continuous, and specialty varieties. Whether you’re looking to add stability to a long, narrow track or we can help you avoid belt failures and — more importantly — maintain your uptime.

Lacing

Allowing for versatility and flexibility, lacing is a way to connect and disconnect the ends of your belt. Rather than utilizing an endless belt, you can use a laced belt to ensure that maintenance, cleaning, and repairs are easier to effect. Great Lakes Belting offers all major forms of belt lacing, including plastic spiral and hinged plate, Alligator, Alligator staple, and Clipper.

Sidewalls

If you’re transporting at steep angles or just need a sturdier, more rugged solution, sidewalls are your best option. Engineered to ensure that your materials stay in place, a well-designed sidewall conveyor belt can transport along steep inclines that may cause other belts to fail. To discuss your application and learn what kind of belting solution is best for you, reach out to us today via our contact page.

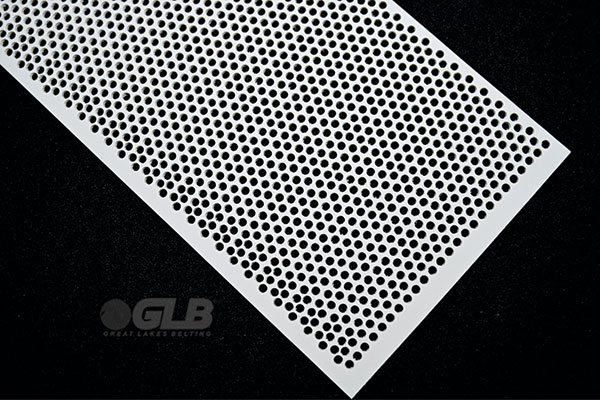

Perforating and Hole Punching

When designing a custom conveying system, it’s essential that all of your pieces line up perfectly. Efficiency is often determined by fractions of inches, and that’s where Great Lakes Belting shines. Working to understand your process, we can deliver accurately spaced, on-target perforating and hole punching so that you can be confident that your system is operating at peak efficiency.

Splicing

For the strongest, longest lasting splices, trust the team at Great Lakes Belting. Whether you need SFL splices, finger splices, or step splices, we can help you create a durable endless belt that will stand up to the rigors of your operation. If you want increased adhesion, improved flexibility, or just rock-solid reliability, you can rest assured that our team can rise to the challenge.

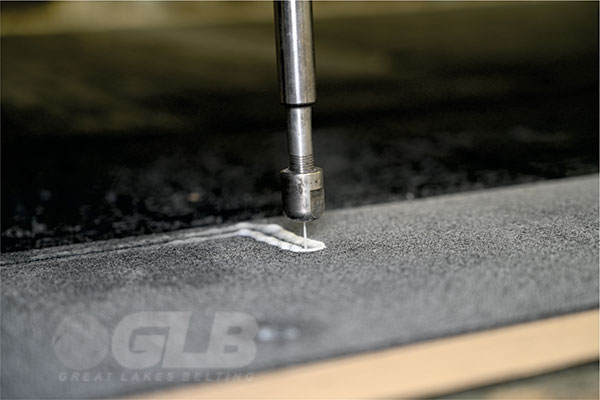

Waterjet Cutting

With the ability to precision cut and manufacture essential components with our waterjet cutting equipment, no other belting supplier offers as much versatility as Great Lakes Belting. Our team can sit down with you, discuss your needs, work out a list of necessary parts, and get to work crafting the belting solutions that your line requires. If you need something and it can’t be found anywhere else, we’re here to make it happen.