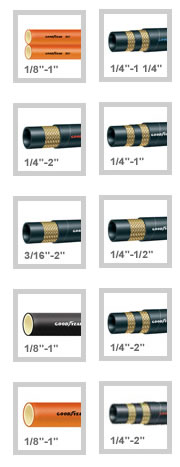

Goodyear Hydraulic Hoses

Designers and engineers are discovering new applications for hydraulic power. Whether the application is construction, mining, agriculture, manufacturing or transportation, Goodyear has a hose to meet the diverse needs of your customers, because Goodyear provides hose products that meet all major global hose standards. Produced to ISO 9001 certification, Goodyear’s hydraulic hoses undergo state-of-the-art manufacturing processes and meet the applied international standards of SAE J517, EN 853, EN 854, EN 855, EN 857, and DIN 20023.

With Goodyear, Traction is your one source for a wide selection of high-performance hydraulic hose fittings, covering a wide range of designs, shapes, sizes and pressure ratings. With low, medium and high-pressure fittings available for braided, spiral and thermoplastic hose. Fittings include Ultra-Crimp™ (1-piece), Uni-Crimp™ (2-piece), Dual-Grip™ (2-piece) and Field- Grip™ (reattachable). Our line of 21 thread ends include SAE, NPTF, JIC, British Standard, DIN and JIS. End styles include straights, swivels, elbows and flanges. Find the fittings and threads you need, from one source.

Choice of Goodyear Crimpers to complete the total assembly solution.

Bite-to-Wire

These one-piece crimp fittings provide maximum coupling retention on one and two braid hose as well as four and six spiral hose. Serrations penetrate the cover with a powerful bite into the wire reinforcement, resulting in even hose compression.

No Skive

Assemblies made faster, with fewer steps and less mess.

Full Length Crimp

Maximum coupling retention for a safe and longer lasting assembly; easier to crimp with a lower profile.

Zinc Plating

Offers corrosion resistance for extended hose assembly and fitting life, easily surpassing the corrosion resistance of SAE ASTM B117.

Kuriyama of America, Inc.

Great Lakes Belting & Supply Corporation provides a complete line of Kuriyama thermoplastic, rubber and metal hose products and accessories including couplings and fittings, for use in industrial and commercial applications. Some of the Kuriyama products we carry include:

- Alfagomma® Hydraulic Hoses and Fittings

- Hose Tec® Metal Hose

- PVC Suction Hose (Tigerflex®)

- Ducting Hose, Tiger Duct™, Tigerflex®, and Neoduct®

- Alfagomma® Rubber Hose and Sheet Rubber

- Kuri Tec® Thermoplastic Hose and Tubing

- Discharge Hose

- Coupling and Accessories

Thermoid® | HBD Industries

Great Lakes Belting & Supply Corporation provides a complete line of Thermoid® industrial hoses and fittings, and well as industrial ducting products. Some of the most popular lines we carry include:

Flex King®

An outstanding example of all around, all quality ducting. This line offers a broad range of base fabrics, plies, coatings, and sizes. All have a wire helix completely enclosed for a smooth, reliable, flexible operation.

APPLICATIONS: Applications cover fume control, cool or warm ventilation, hot air, light materials handling——even projects where rot, mold and mildew are a problem. FlexKing is available in a variety of neoprene coated fabrics. Soft cuffs, neoprene dip coatings, and wearstrips are available on request.

Ultraflex®

The Ultraflex ducting line delivers high performance service to a wide range of applications. The variety of thermoplastic materials makes this line exceptionally versatile. Flexibility and compressibility also makes it ideal for many difficult, hard to handle applications. Its toughness, weatherability, and resistance to chemicals and abrasion allow it to take on the most demanding jobs.

APPLICATIONS: Venting systems for chemical fumes; dust collection; exhausting gases; air movement. Ultraflex Type TPU is also good for lawn and garden applications including chip handling, leaf and grass loading, straw blowing; industrial vacuum systems; transfer of plastic pellets; dry bulk material handling systems; agricultural product material handling; woodworking applications including transfer of sawdust and wood chips.

Neoflex®

Neoflex ducting is designed for conveying hot or cold temperature air and fume control applications ranging from -40F to 300F. It is not recommended for applications involving the movement of liquids or abrasive materials, or for negative pressure applications. Its excellent flexibility allows for easy installation around obstructions and sharp bends.

APPLICATIONS: Typical applications include portable generator cooling, heater ducts and electronic equipment cooling.

Silflex®

Silflex ducting products are designed to handle extreme high and low temperature air handling applications ranging from -80F to 550F. They are not recommended for applications involving the movement of liquids or abrasive materials, or for negative pressure applications. This ducting is extremely flexible and can be easily installed around obstructions and sharp bends.

APPLICATIONS: Typical applications include electronic equipment cooling, paper processing equipment, engine compartment air handling, and fume removal from aluminum and glass manufacturing.